FLI is suitable for offline operations without incurring rig-time.

The FLI rig-up is fast and simple and the footprint is tiny. The ease of moving from well-to-well makes FLI ideal for batch operations, enabling multiple wells to be surveyed in a short period of time.

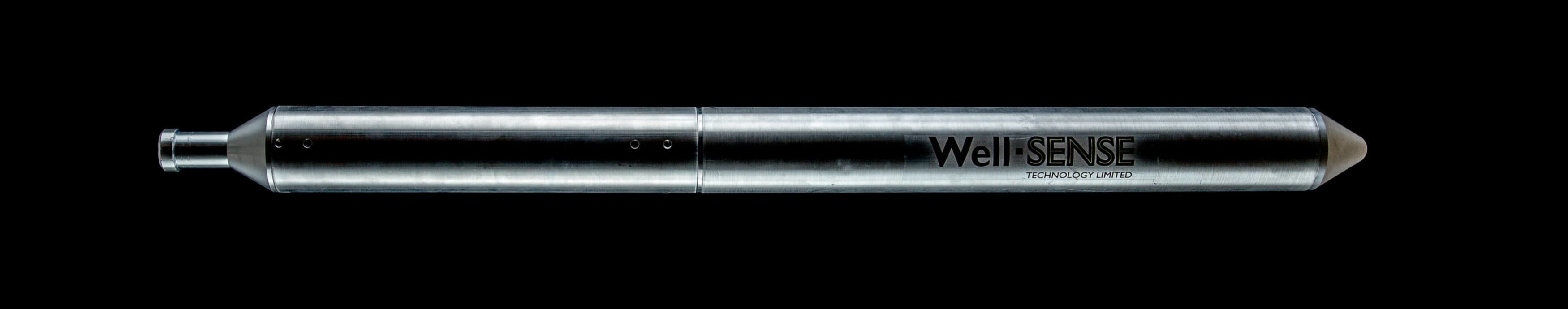

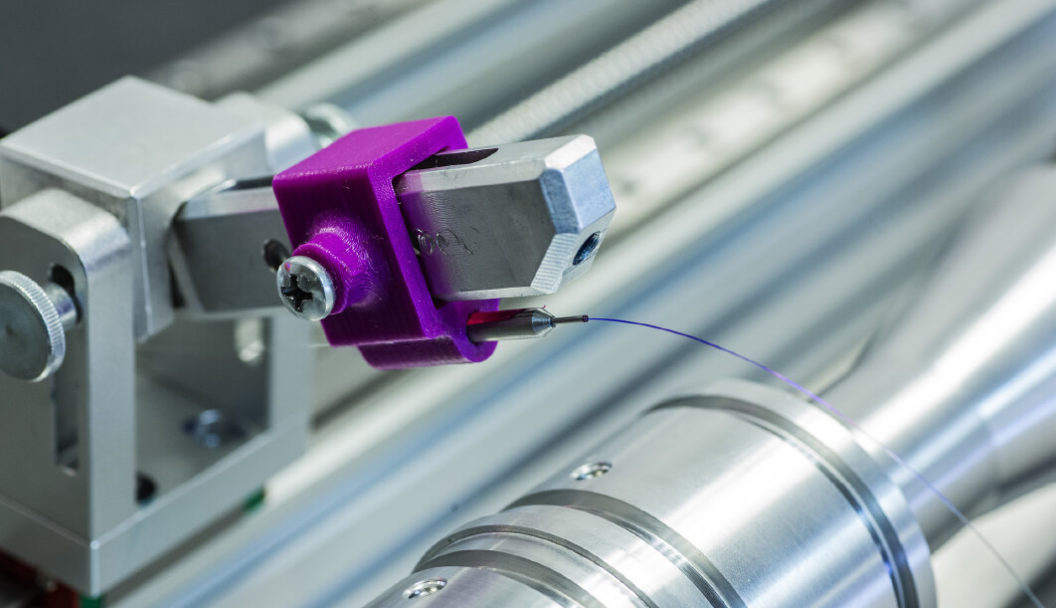

Rig-up of the system is simplified through the use of a plug and play connection that is installed on top of each FLI probe. Connection to the pressure-controlled release assembly requires removal of a retaining nut, insertion of the probe, which has a standard fish neck profile, into the launcher and re-fitting the nut. The entire assembly is then ready to be lifted and installed onto the well, with a connection to a standard lubricator section and crossover.

FLI enables precise depth control and rapid data.

We connect our surface light source and data recorder to the optical fibre in the FLI probe through a pressure control fitting in the launcher, which is fixed at the wellhead. This means we know the exact start and end point of the fibre, giving us precise depth control.

Standard procedures for pressure test and opening of the well are completed ahead of deployment. The FLI probe is launched by stroking a hydraulic piston in the release assembly using a hand pump, which activates the release mechanism.

Data is captured both during the probe’s descent into the well and during the time the probe is stationary at total depth. Find out more about these types of surveys here.

FLI reduces risk and increases efficiency.

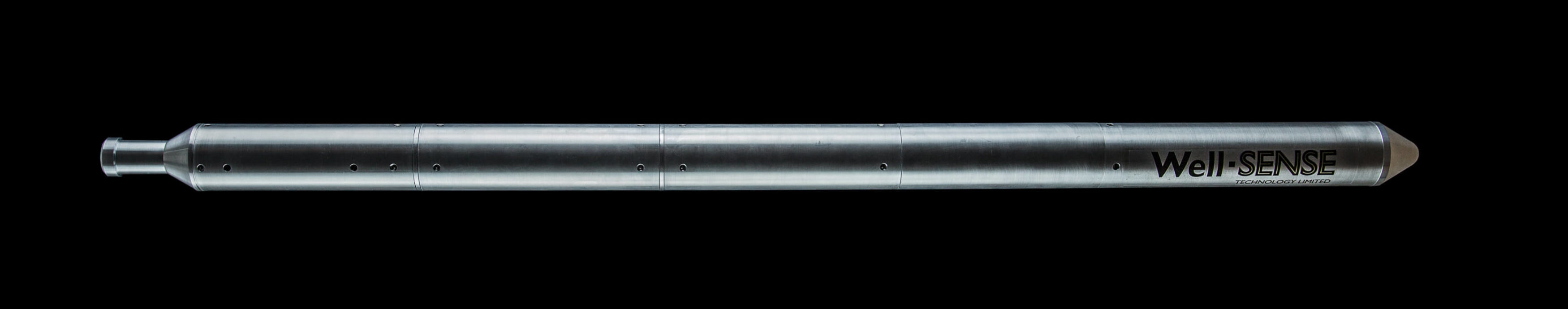

At the end of the survey, rig-down is almost immediate. We simply cut the fibre and remove the launcher from the wellhead. For most projects we leave the aluminium probe and fibre in the well. Due to their lightweight composition, and the fibre’s exceedingly small volume, they do not limit any future well operations or present any risk of extended fishing.

Compared with traditional well surveying and intervention methods, the FLI system provides significant savings in site footprint, personnel, logistics, downtime and associated costs. Reduction of personnel on site is a significant HSE advantage in these challenging times.

View our Rig-Up Demo Video

View our Technology Concept Animation