‘Active-FLI’ sensor technology is proven in first commercial deployment

11 November 2019

Downhole sensing technology specialist, Well-SENSE, has successfully proven its ‘Active-FLI’ technology with the completion of its first commercial onshore well survey for a major E&P operator at a test well in Texas, USA.

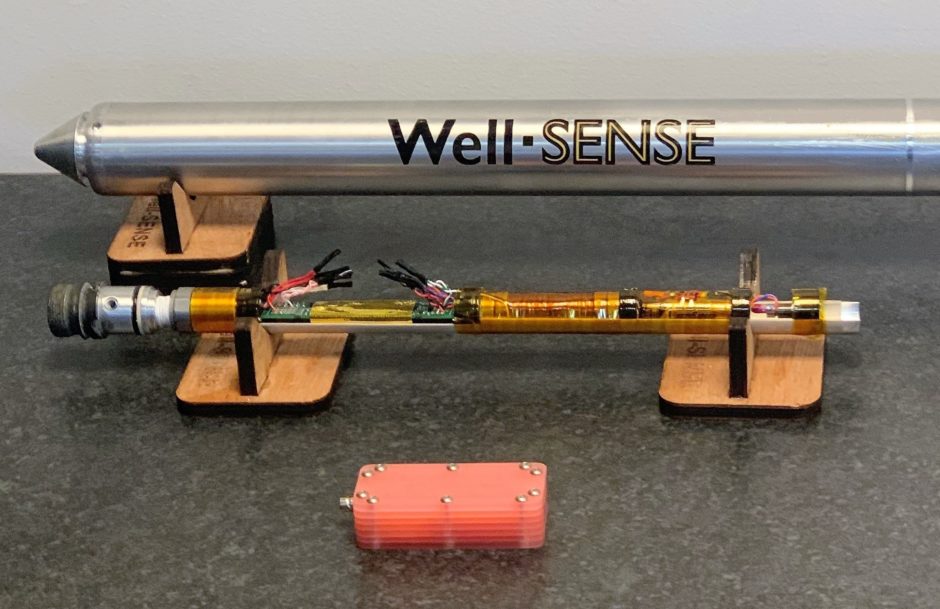

The Aberdeen headquartered company’s ‘Active’ technology enhances their FiberLine Intervention (FLI) distributed sensing capability with an add-on package of electronic and optical sensors that capture single-point readings along the wellbore.

Active-FLI is the only sensing system on the market to combine distributed and single point data in a fast and portable well interrogation solution. It greatly reduces the operational footprint and risk for the operator, using less time, personnel, space and equipment and can reduce survey costs by up to 90% depending on the application and well environment.

As part of this project, and for the first time, Well-SENSE also demonstrated its own miniature surface recording device. A ‘first look’ set of results was provided to the operator immediately after reaching total well depth. Real-time data logging continued for five hours then a complete report was submitted within 24 hours of the end of the survey. This saw the E&P firm receiving high quality results at least 50-75% faster than conventional wireline logging.

The scope of work required Well-SENSE to provide an accurate pressure and temperature gradient survey for the entire wellbore, combined with a casing collar locator survey and bottom hole pressure and temperature monitoring of the operator’s 1,500ft test well. The well also contained a combination of steel and fiberglass casing which FLI was required to locate, along with confirmation of total well depth. The results would be used to enhance the operator’s well intelligence for future operations and to verify Active-FLI’s capabilities.

Whilst descending through the well, the CCL survey confirmed the depth of the steel and fiberglass casing joints along with the total accessible depth of the well. The CCL data also identified the location of multiple geophone sensors mounted behind the fiberglass casing. The bottom hole temperature data matched a prior logging run within 0.1 degree Fahrenheit and the bottom hole pressure reading was within 4% of the anticipated hydrostatic pressure.

Craig Feherty, Well-SENSE CEO said: “Our FLI systems can deliver rich and accurate well data quickly and cost effectively. They are small and easy to ship and only require one person to operate. For this project, from the initial enquiry, through to product manufacture in the UK, delivery to the USA, deployment and completion, with a final report submitted to the client, it took just six weeks.

“FLI’s success in Texas validates our Active technology in terms of system reliability, data accuracy and quality, and confirms that our package of sensors are eminently suitable for conventional oil and gas applications.

"We have an exciting time ahead, with a number of commercial deployment opportunities in the pipeline plus further R&D planned to add to the product portfolio. The ever-increasing interest we are receiving from industry supports our belief that this technology is a real game changer.”

With its headquarters and R&D hub in Aberdeen, Well-SENSE also has a manufacturing facility in Hampshire, UK and a commercial operation in Houston, USA.

Well-SENSE, alongside ClearWELL, Unity and Pragma, is part of the Aberdeen-based FrontRow Energy Technology Group.